Selection about Diamond Grinding Wheel's diamond particle size and concentration

September 17, 2018

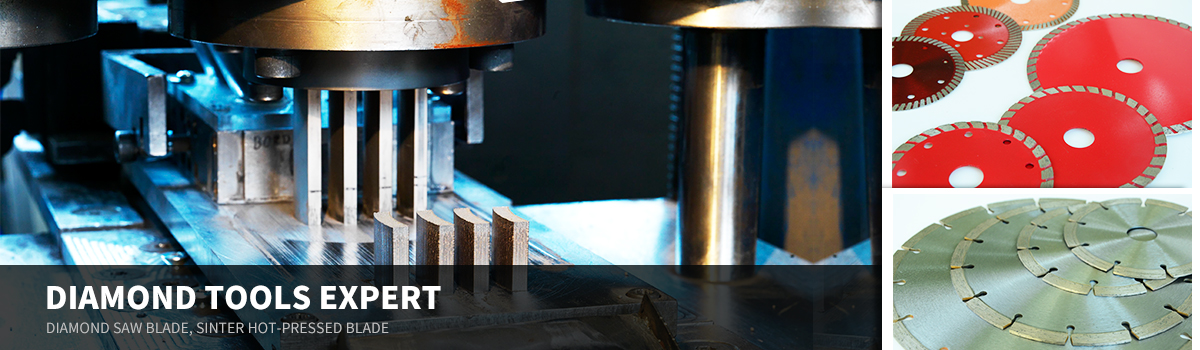

A diamond wheel series: Synthetic diamond, also known as "industrial diamond", is the hardest substance in nature known today, like the natural diamond. Due to its high hardness, compressive strength and wear resistance, acid and alkali resistance, and good thermal conductivity and semiconductor properties, it can be widely used in metallurgy, machinery, geology and petroleum. , electronics, optics, architecture, stone and other fields. Synthetic diamond grinding wheel is a synthetic diamond product with artificial diamond as the main raw material and other metal powders formed by high temperature and high pressure. It can be widely used in the grinding of hard alloys, non-ferrous metals and non-metals.

The particle size of the second particle size is selected by the particle size number. The thickness of the particle size directly affects the surface roughness of the workpiece, the grinding efficiency and the wear loss of the tool. In principle, the particle size is selected to be as coarse as possible under the conditions that meet the requirements of the workpiece. This can improve the grinding efficiency and reduce the loss of the grinding tool. The diamond particle size is generally divided into the grinding process using the coarse grain grinding 30#-120#. Grinding 120#-240# Fine grinding 240#-W40 Grinding and polishing W40-W1

The three-component agent is selected from synthetic diamond grinding wheels, which are generally divided into resin grinding wheel, metal grinding wheel, ceramic grinding wheel and electroplating grinding wheel according to different bonding agents. Different binders have different properties, and suitable binders should be selected according to different processing objects and requirements. Bonding agent code Main use resin binder B is used for cutting and grinding of cemented carbide, glass, ceramics, stone and gemstones. The metal bond agent M is used for heavy-duty cutting, grinding and wear resistance of cemented carbide, glass, ceramics, stone, gemstone, etc. Ceramic bond V is used for dry and wet grinding of various steels and cast irons and is more suitable for grinding long shafts and silks. Electroplating bond D is used for special profiles of various materials, grinding of small holes and cutting of valuable materials.

The concentration of the four concentrations refers to the content of the synthetic diamond in the abrasive layer of the abrasive. 1 resin bond grinding wheel generally uses 50%-100% concentration; most of them use 75%, when the finish is higher than 75%, the grinding wheel and the longer service life of the grinding wheel can be 100% or more. . 2 The metal bond product generally adopts a concentration of 25%-150%; wherein the coarse-grained cutting saw blade generally has a lower concentration, that is, 25-50%, and the fine particle size is higher; and other metal bond grinding wheels generally require concentration. It is required to be 50%-100%. In general, coarse grinding uses higher concentrations, semi-finishing uses medium concentrations, and fine grinding, polishing, etc. uses higher concentrations. Concentration Abrasive Content Volume % Carat/cm3 25% 6.25 1.1 50% 12.5 2.2 75% 18.75 3.3 100% 25 4.4 125% 31.25 5.5