PCD Grinidng Cup Wheel

In the application of uncoated superabrasive grinding wheels, there are three increasingly prominent problems: insufficient abrasive holding power, insufficient abrasive particle protection, and poor chemical reaction between the abrasive particles and the binder (using metal and The grinding wheel of the ceramic bond has only the last two problems). The use of superabrasive coating technology helps solve these three problems, which improves the grinding performance of the grinding wheel. The...

Diamond Grinding wheel selection is important in grinding

Grinding is generally used as the final process of workpiece machining. Its task is to ensure that the product parts can meet the precision and surface quality required on the drawings. Grinding surface roughness is closely related to the accuracy of the part, and certain accuracy should have a corresponding surface roughness. Under normal circumstances, to effectively control the size, the roughness Ra value should not exceed one-eighth of the dimensional tolerance. The effect of the grinding...

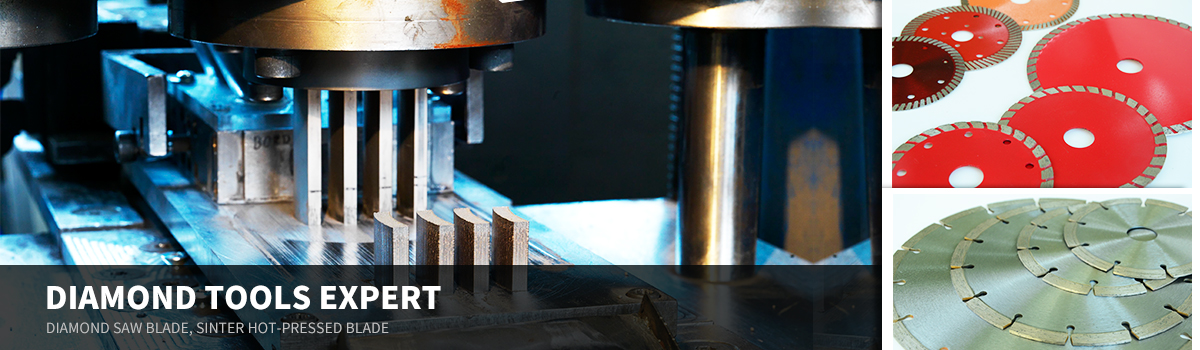

Make the diamond saw blade stronger

Any company that wants to be bigger and stronger will be based on products and find a way to suit itself in its operational strategy. And we always consider the value of the product, the added value of the product, which is also our operational thinking. Mr. Ji, director of the diamond saw blade market, believes that “marketing is not profound, so-called innovation is not difficult, and it can be done in place. It is most important to look at the market and grasp the market pulse. We advocate...

Diamond wire multi-wire cutting technology

In the production workshop of the second phase of Inner Mongolia Photovoltaic Materials Co., Ltd., more than 100 single crystal silicon furnaces are all open and are being produced at full capacity. The drawn single crystal silicon rods are directly sent to the automated production line with diamond wire multi-wire cutting as the core technology, and processed into ultra-thin and high-efficiency single crystal silicon wafers for solar cells. This set of technology referred to as DW is...

Knowledge of Diamond Saw Blade

Diamond saw blade is a cutting tool, widely used in the processing of hard and brittle materials such as stone and ceramics. The diamond saw blade is mainly composed of two parts; the base body and the cutter head. The base body is the main support part of the bond cutter head, and the cutter head It is the part that cuts during use. The cutter head will continue to be consumed during use, but the matrix will not. The reason why the cutter head can play the role of cutting is that it contains...

Diamond Core Drill Bit

Abstract Recently, a good news came from the Yuanlu 30 well in northeastern Sichuan. The impregnated diamond drill bit developed by Shengli Oilfield Drilling Institute was successfully applied in the well and created a new record of 158.56 meters in a single diamond drill bit in the region. The impregnated diamond drill bit is for the Shengli Oilfield Drilling Institute... A few days ago, a good news came from the Yuanlu 30 well in northeastern Sichuan. The impregnated diamond drill bit...

Diamond Grinding Wheel

The diamond grinding wheel is one of the strong and solid products in the grinding wheel industry, but there will also be a situation of violent edge. What is the reason? Below Dongguan Mingfeng Glass Machinery Parts Co., Ltd. for you to simply say: 1. The nature of the diamond grinding wheel processing material itself is not suitable for grinding; the model and specification of the diamond grinding wheel are destined to cut the product, and what kind of product to edging. For a simple analogy,...

Application of diamond saw blade in building cutting-Construction Tools

The diamond saw blades produced today have introduced a number of important innovations in recent years, based on the evolution of the tools and mechanical technologies used. Controlled and selectively dismantled technology is based primarily on diamond tools and can be used for reinforced concrete and concrete operations in addition to rock. The diamond saw blade makes it possible to work selectively and ecologically, that is, to work only on a specific area of the building and to maintain the...

Diamond Wire Saw

The project “Research and Application of High-Performance New Diamond Tools in the Construction Industry” undertaken by the National Special Mineral Materials Engineering Technology Research Center of Guangxi Guilin Institute of Mineral Geology was approved on March 4 by an expert meeting organized by the Science and Technology Department of the Autonomous Region. Experts believe that the project has adopted the original tooling design in the country, and applied advanced technology and...

Selection about Diamond Grinding Wheel's diamond particle size and concentration

A diamond wheel series: Synthetic diamond, also known as "industrial diamond", is the hardest substance in nature known today, like the natural diamond. Due to its high hardness, compressive strength and wear resistance, acid and alkali resistance, and good thermal conductivity and semiconductor properties, it can be widely used in metallurgy, machinery, geology and petroleum. , electronics, optics, architecture, stone and other fields. Synthetic diamond grinding wheel is a synthetic diamond...

Removing bridge without explosion and dust free by Diamond wire saw

Wire saw with diamond drill bit, slowly cut the reinforced concrete concrete slab on the bridge surface, two large cranes lightly sway the long arm, lift a piece of 4 ton concrete slab, gently put it off the bridge On the bank of the river more than 20 meters away, there is no harsh explosion, no flying dust &hel... A wire saw with a diamond drill bit slowly cuts the reinforced concrete concrete slab on the bridge deck. The two large cranes lighten the long arm and lift a 4-ton concrete...

How to selecte Diamond Grinding Cup Wheel

First, the metal alloy sintered diamond grinding wheel is commonly known as the diamond wheel: the diamond-containing part of the diamond wheel is called the working layer, the working layer is mostly the ring shape, so it is also called the working ring, the working ring height is called the work height, and the working width is changed. Known as the ring width, the outer portion of the ring width at the diameter of the grinding wheel is called the outer ring, and the inner side is called the...

Concrete cutting blade

Cutting saw blades or saw blades are often used by many companies that use metal circular saws. This is a common problem, and other companies have headaches. After all, the consumption of saw blades is also a big expense for enterprises. So is there any way to minimize this loss? First of all, let's analyze the cause of damage to the circular saw blade: In the installation of circular saw blade must also be properly installed, more than a few inspections, the installation is not correct will...

The life analysis of Diamond saw blade

Diamond saw blades are an indispensable tool for stone mining and processing. The factors that determine their efficiency and service life are various. In general, the following parameters are mainly included. First, the sawing parameters (1) Saw blade line speed: In actual work, the linear speed of the diamond circular saw blade is limited by the condition of the equipment, the quality of the saw blade and the nature of the sawed stone. From the optimum saw blade life and sawing efficiency,...

Diamond Bead Wire For Granite Cutting

It is well known that the use of diamond bead wire saws for marble cutting in marble mining is a very mature technology. However, after Italy Ma Ruini (MARINI) the company's engineering and technical staff years of unremitting efforts, the application of diamond Wire Saw cutting granite in granite mining process has become a reality. China's traditional granite mining process is a combination of vertical flame cutting and horizontal blasting, resulting in a great waste of resources. This paper...

Diamond Core Drill

The diamond drill is not only used for a long time, but also can be reused. The diamond drill that is returned to the factory is similar to the diamond drill used at the factory, and it can save a lot of drilling costs. The quality of the drill bit, the type of drill bit and the suitability of the formation lithology play an important role in accelerating the drilling speed and increasing the footage of a single drill. Drilling an oil and gas well generally requires the use of multiple drills...

Introduction About Grinding Cup Wheel

Metal bond diamond grinding wheel according to the different manufacturing methods are mainly two types of sintered plating. In order to give full play to the role of superhard abrasive, foreign countries began to develop a new type of grinding wheel with high-temperature brazing technology from the early 1990s, namely a single-layer high-temperature brazing superhard abrasive grinding wheel. At present, this type of grinding wheel is still in the research and development stage. Sintered...

How to use a circular saw blade?

Maintenance is necessary regardless of whether it is a human or a product workpiece. A circular saw blade is no exception. In particular, some high-grade circular saw blades can easily reduce the service life of the circular saw blade if it is not maintained properly, resulting in an increase in saving costs. Before using the circular saw blade: Before the use of the circular saw blade, it must be ensured that the cutting workpiece is properly fixed, the positioning of the profile is in line...

Circular diamond saw blade

An official with the Ministry of Commerce (MOC) said on Saturday that China opposes abuses of trade remedies about the diamond saw blade anti-dumping and hopes that trade disputes with America can be resolved as soon as possible under the WTO dispute-settlement mechanism, he said this is. China is concerned about the disputes with the United States that have remained unresolved after negotiations and consultations between the two sides, the official said. He accused the United States of...

Diamond Grinding Wheel

1. The appearance of good uniformity and no cracks are the basic appearance of the high-quality grinding wheel; 2. Excellent packaging and printing anti-counterfeiting barcodes are the difference between genuine factory products and counterfeit goods; 3. The general rule of cutting and grinding is that the amount of iron is less, the wear is low, the grinding wheel is too hard, the amount of iron removed is small, the wear is too great, and the quality of the material is too bad. The inner...

Stone cutting disc

[New weather after year, cutting machine through the bottom price. The lowest price of the entire network, all kinds of the custom cutting machine will be 50% discount wholesale order price, a small piece of drawings to achieve a three-dimensional 3D cutting machine parts, where to set where customers no longer have to worry about no supply and reserve price. What are you waiting for? The reserve price is known to you. You haven't asked if the inquiry is low. The stonecutter consists of a...

Diamond saw blade

Diamond saw blade is a cutting tool, widely used in the processing of hard and brittle materials such as stone, concrete and ceramics. The diamond saw blade is mainly composed of two parts; the base body and the cutter head. The main body is the main support part of the bonder head, and the cutter head is the part that is cut during use. The cutter head will be continuously consumed during use, while the base body will not, and the cutter head can cut. The role is because it contains diamond,...